Precision and Consistency: Automated control systems ensure that temperature and other parameters are maintained within tight tolerances, leading to more uniform treatment results.

Increased Efficiency: Automation optimizes energy consumption by controlling the furnace’s heating elements and adjusting them dynamically, reducing waste and lowering operational costs.

Productivity: With automation, heat treatment cycles can be executed faster and more efficiently, leading to higher throughput and reduced downtime.

Safety: Automation reduces the need for human operators to be physically present near high-temperature equipment, minimizing exposure to hazardous environments.

Data Logging and Analysis: Automated systems provide detailed logs of temperature profiles, process timings, and other critical variables, allowing for process optimization, traceability, and quality assurance.

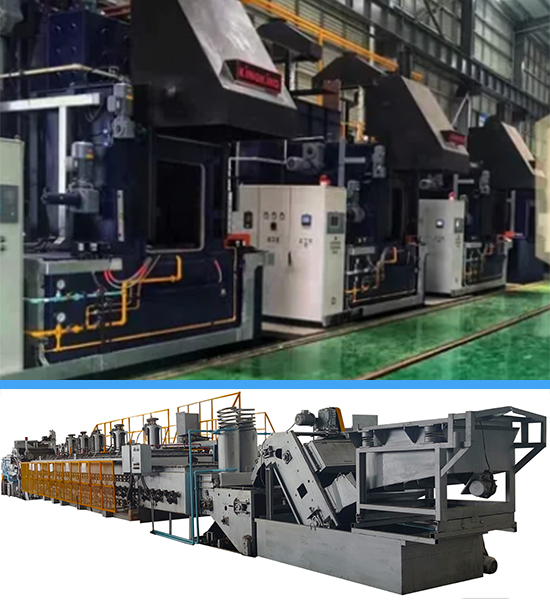

Batch Furnace Automation: For operations where a batch of parts is loaded, treated, and cooled as a unit. Automation ensures precise control of temperature and timing for consistent quality across all parts in the batch.

Continuous Furnace Automation: For high-volume, continuous operations where parts move through the furnace on conveyors or rollers. Automation coordinates the flow of parts, temperature zones, and cooling processes to maintain consistent quality and throughput.

Integration with IoT and Industry 4.0: More advanced automation systems are integrating with IoT sensors, enabling predictive maintenance and real-time analytics for optimized performance.

AI and Machine Learning: AI-driven algorithms are being used to predict optimal heat treatment cycles, reduce energy consumption, and enhance process outcomes based on data patterns.

Energy Recovery and Sustainability: Innovations in heat recovery systems are being integrated with automation to capture and reuse waste heat, further reducing the energy footprint of heat treatment furnaces.